BMW i3's Motor Mount Menace: Your Ultimate Guide

Alright, BMW i3 enthusiasts, gather 'round! You know that sudden jolt during a punchy acceleration? It's not your caffeine kick. That's your i3 telling you about its notorious motor mount hiccup. Buckle up, because we're about to dive deep into this pesky problem and show you how to kick it to the curb. Stay with me; this is going to be one electrifying ride!

The Problem Explained

Picture this: You're feeling gutsy, flooring the accelerator, and then – BAM! – there's that uncalled-for jolt. But what's really happening under the hood? It's like your i3's electric motor is having a party, revving up to crazy speeds when there's no load (like when your rear wheels get some air).

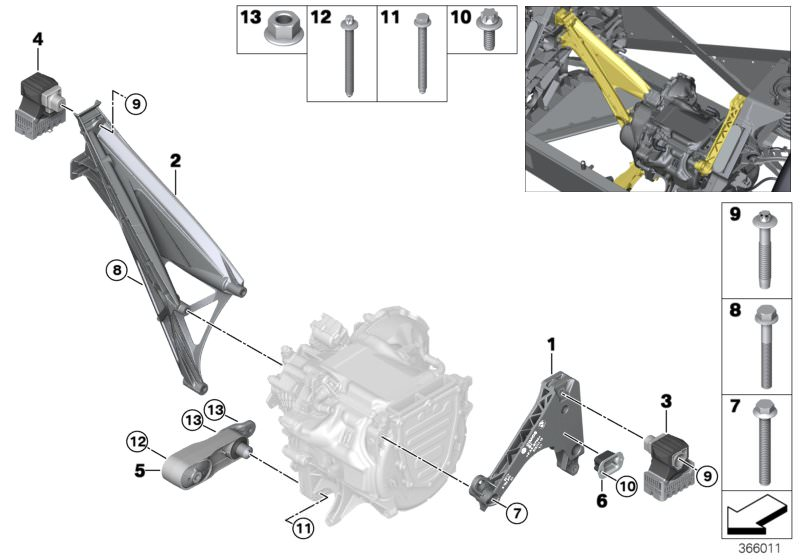

But when those tires slam back to the ground, the force can damage the motor mount bolt. And if it's the left side mount in a BEV or both in a REX, you're in for a shock, literally. It's like dancing on ice with tap shoes; something's bound to crack.

And if you think, "Oh, a little jolt won't hurt," remember, you're playing with high-voltage components. Mess it up, and your wallet's in for a jolt too.

The Affected Vehicles

Alright, don't start panicking just yet. This isn't a universal BMW i3 phenomenon. We're talking about the BMW I01 i3 BEV and i3 REX models produced between October 2013 and November 2015. So, if you're cruising in one from this period, give me your full attention. If not, still stick around — you never know when this intel might come in handy for a friend, or let's be honest, for some car trivia on a random Tuesday night.

Diagnosing the Issue

Time to roll up those sleeves and play detective. You wouldn’t ignore a mysterious rattle in your attic, so don’t neglect this either.

Here's how to check if your i3 is sounding the motor-mount distress call:

- First, if you've been doing any daredevil driving that involves making your i3 fly (even just a bit), that's clue number one.

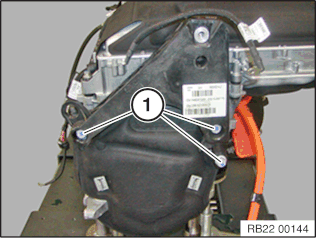

- Inspect the motor mount bolt, especially on the left side for BEVs and both sides for REX models. It's like checking for a sprained ankle after a misstep; see if it's out of place or damaged.

- Check out the plastic mount bracket. If it looks more twisted than the plot of a telenovela, you've got a problem.

- And if you've been brushing off that weird noise while driving, it's not just your imagination. It could be the high-voltage components (EME, KLE) crying out for help.

Remember, it's not just about spotting the issue. If these mounts are compromised, they can be the evil domino that starts a chain reaction of damage to other parts of your car. So, give your i3 the attention it deserves, and it'll thank you with a smooth ride.

Solution: Hardware & DIY Tips

Alright, gearheads, here's where the rubber meets the road. If you’ve found that your i3's got the motor mount blues, don't despair. Let’s talk solutions.

A. The Official Way

BMW’s textbook fix is to replace both engine mounts and that left engine bracket. However, if your i3’s warranty has clocked out, brace yourself. The dealer might hit you with a quote that’ll make you think they’re including a golden motor.

Why?

Because, for some baffling reason, they insist on removing the whole engine assembly just to swap out the bracket.

Overkill? You bet.

B. The My Way

I've swapped out a few of these brackets without yanking out the engine. Total time? Less than two hours. The tricky bit? Those three pesky 16mm bolts holding the bracket. But with a little creativity (and a makeshift tool), they're no match for some DIY spirit.

Quick Tip: If you're planning to go rogue and do it yourself, arm yourself with tools like the Matco Tools Serpentine Belt Tool MSBT15.

Or, if you're feeling crafty, weld a ⅜ 16mm socket to a 19mm wrench. Just remember, before you dive in, disconnect the 12V battery negative lead.

Safety first, always!

Note: Before you seal the deal, ensure you:

- Check the high-voltage cable under the drive shaft sleeve.

- Examine bracing struts for paintwork damage. Rust is not your friend.

- Inspect the battery voltage line near the iso-fix strip.

- Survey all visible electrical connectors.

- Peek at the inner drive shaft CV boots.

And for those brave souls ready to tackle this, here's a forum thread that might help. (But seriously, don’t drill holes in the rear subframe. Just...why?)

Disclaimer: While I've had success with the DIY method, remember this isn’t a BMW-sanctioned procedure. Always consult with professionals when in doubt.

Solution: Software Update

Now, onto the digital side of things. Just like your phone needs periodic updates to keep it running smoothly, your i3 could use a software pick-me-up.

The Issue with the Old Software

The original software's reflexes were... well, let's just say not Olympic-level. Here's the drama: an electric motor can rev up to a wild 11k RPM almost instantly. But if the traction control is daydreaming and takes too long to intervene, things get messy real quick. With a combustion engine? Not a huge deal. With an electric motor? Houston, we have a problem.

Enter the Software Savior

Starting from the I-Level 15-11-502 software update, BMW tackled this issue head-on. This update ensures that the motor electronics cut the power to the electric motor faster, preventing it from spinning out of control.

Now, I've heard whispers about reduced power output or weaker regenerative braking after the update. But let's bust that myth: these claims are as real as unicorns. With the software upgrade, your i3 remains the electric dynamo it always was.

DIY Software Update

If you’re feeling tech-savvy and wish to update the software yourself, tools like E-Sys can be your ally. But if you've got access to the BMW ISTA application, make sure you have the Programming Data on hand. It’ll make the process smoother than a fresh jar of peanut butter.

Remember, folks, technology is only as good as its latest update. So keep your i3’s software in tip-top shape and enjoy the drive!

Conclusion & Recommendations

Alright, fellow i3 aficionados, we've turbocharged through the nitty-gritty of the motor mount issue, and here's the takeaway.

The Real Deal

Driving is unpredictable. Whether you're cruising down Route 66 or navigating the urban jungle, you never truly know what's around the bend. If you're piloting a 2016 or older BMW i3, don't just cross your fingers and hope for the best. Be proactive.

The Game Plan

- Check those Motor Mounts: Like a doctor's check-up, a quick peek now can save a lot of pain later.

- Hardware Solutions: If there's an issue, decide between the official BMW method and the DIY route, depending on your comfort and budget. But remember, cutting corners can lead to detours down the road.

- Software Update: Keep your i3's digital brain sharp and updated. It's not just about performance; it's about safety.

Final Thoughts:Your BMW i3 is a marvel of engineering and design. It deserves care and attention. Address the motor mount issue head-on, grab that software update, and you'll ensure your ride remains as electrifying as the day you first drove it.

Safe travels and happy driving!